Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

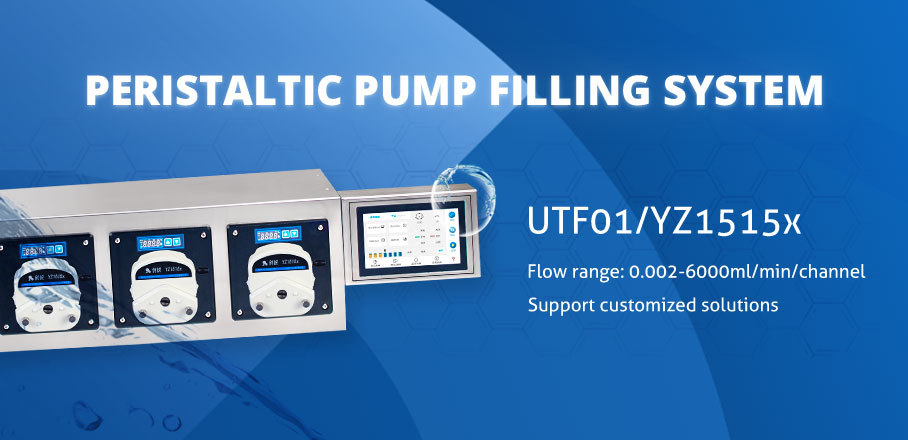

Model No.: UTF01

Brand: Chuangrui

Drive Model: Utf01

Pump Head: Yz1515x / Yz2515x / Tx315 / Dg Series / Kz25 Series

Max Flow: 6000ml/Min

Max Channel: 32 (Support Customized)

Power Supply: Ac110v Or Ac220v

MOQ: 1set

Warranty: 1year

Remote Control: Optional

Application: Filling Pump

OEM Order: Acceptable

Packaging: 1. carton with plastic foam 2. follow client`s requirement

Productivity: 1000sets per set

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 1-3 sets 7days; above 3 sets, can be negotiated

Certificate: CE, ISO9001

HS Code: 9026100000

Port: Tianjian,Shanghai,Beijing

Payment Type: T/T,Paypal

Incoterm: FOB,EXW,Express Delivery

Peristaltic Filling Pump & Customizable filling machine

Multi-channel Peristaltic Pump Filling System UTF (Ultra Filling System)could work alone to dispense the liquid material into the bottles or other containers with our filling nozzles and filling stand , and also could be integrated in and controlled by the packing machine for a complete automatic production system. It can be controlled by start-stop(Passive signal )control,Which can work with your various sensor.It also accept active signal control customized.

The Dispensing Peristaltic Pump is expandable from 2 to 32 channels based on the production line exact requirement.

The Multichannel Peristaltic Pumps is specially designed for multi-channel fast filling of various liquid materials. It supports single-channel membrane button fine-tuning to quickly meet customer calibration needs. At the same time, it supports high-precision calibration in combination with a balance or measuring cup. The pump head can choose 3 rollers, 4 rollers, 6 rollers, etc. to meet the different pulsation requirements of customers, and at the same time, a customized damper can be used with the filling machine to achieve stable and high-precision filling.

The Chemical Liquid Filling Pump can be used for foot switch to control semi-automatic manual filling, and can also be integrated into various production lines that require liquid material filling, such as vaccine filling machines, blister machines, cosmetic filling machines, food packaging machines, etc. The unique external signal control of the Filling Pumps can be perfectly combined with the customer's equipment. It is a good helper for various multi-channel, high-precision and high-efficiency liquid filling pumps.

| Automatic Fill Peristaltic Pump Specifications | ||

| Model | UTF01 | |

| Pump head | YZ2515x | |

| Channel number | 4 is standard | Max 32 channels |

| Pump head in series | 1 is standard | Max 2 heads for each channels |

| Filling volume | 0.1ml-9999.99ml/time | Display adjustment resolution: 0.01ml |

| Filling time | 0.1s-9999.9s/time | Display adjustment resolution: 0.1s |

| Filling times | 0-9999time | "0" is an infinite loop |

| Back suction speed | 0-1000° | Display adjustment resolution: 1° |

| Back suction delay | 0-300rpm | Display adjustment resolution: 1rpm |

| Interval time | 0.5s-9999.9s/time | Display adjustment resolution: 0.1s |

| Channels number | channel / unit (standard),23456 channel / unit (optional) | Scalable up to 32N4 |

| Back suction delay | 0s-60s | Display adjustment resolution: 0.1s |

| Power supply | 220v or 110v optional | |

| External Control | start-stop cable // No bottle no filling function can work with your sensor or PLC. | |

| Suitable pump head & Flow reference (ml/min) | ||||||

| Pump head | YZ1515x | YZ2515x | DG1~12(6) | DG1~12(10) | TX315 | KZ25 |

|  |  |  |  | ||

| 0.1-600rpm | 0.1-600rpm | 0.1-100rpm | 0.1-100rpm | 0.1-400rpm | 0.1-300rpm | |

| Tube | 13|14|19|16|25|17|18# | 15# 24# | 0.5*0.8,1*1,2*1,2.4*0.8,3*1 | 13|14|19|16|25|17|18# | 15|24|35|36# | |

| UTF01 | 0.007-2280 | 0.17-1740 | 0.002~36 | 0.0015~27 | 0.008-2000 | 1-3000 |

| Noted: 1.The defaulted model we will send is UTF0104Y2W1 with silicon tube 24# 2.Defaulted channel number is 1 ,If you need multiple pls contact us 3, Support multiple channels customized, more info ,pls contact us | ||||||

| Order Number | Model | Pump head | Channel number | Pump head in series | Tube model | Max Flow per head |

| UTF0102Y2W1 | UTF01 | YZ2515x(White) | 2 | 1 | 18# | 2280ml/min |

| UTF0104Y2W1 | 4 | |||||

| UTF0108Y2W1 | 8 | |||||

| UTF0112Y2W1 | 12 | |||||

| UTF0116Y2W1 | 16 | |||||

| UTF0120Y2W1 | 20 | |||||

| UTF0124Y2W1 | 24 | |||||

| UTF0128Y2W1 | 28 | |||||

| UTF0132Y2W1 | 32 | |||||

| Tube specifications for the pump tube of YZ2515x . Suitable for litter thicker liquid . Noted : The standard tube which will come with the pump is model 24#, If you need other tube model , pls contact our sales in advance. | ||||||

| Tube model | ID (mm) | OD (mm) | Standard material | Max Flow (ml/min) | Filling capacity | Filling speed (times per hour) |

| 24# | 6.4 | 11.2 | Silicon tube | 1740 | 20-100 ml | 600-2400 |

| 15# | 4.8 | 9.6 | Silicon tube | 1020 | 10-50 ml | 900-2500 |

Product Categories : Peristaltic Pump > Peristaltic Pump Filling System

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.